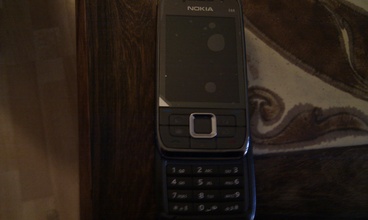

I had decided to give my wife my E66, but my E66 was pretty much worn out. The case had started to fall apart and there was dust beneath the glass protecting the TFT screen.

It is possible to buy spareparts for mobile phones though. Buying them from a local dealer in your country will surely set you back many many dollars. Luckily Ebay came to the rescue. I bought a new fascia housing for my Nokia E66. Only set me back around $10.

The seller states:

NOT supplied fitting manual

Replacing your phone with this new fascia, the preference to phone shop engineering maintainers or alternatively change it by yourself with any of corresponding tools.

So this blogpost constitutes a walkthrough on how to replacing the fascia, in case somebody else decides to revitalizing his or hers aging Nokia E66.

What was in the package from the seller?

I then started to take the old phone apart. Gently, noting where everything went. This is not the time where you want to have leftovers afterwards!

Next up, remove the screws. Notice carefully what screws belongs to what hole. There are 3 different screws on the back.

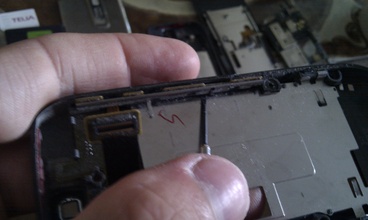

Next seperate the front and the back from the actual phone mainboard. Do this very very carefully. Do not get angry! And do not use excessive force. Everything in the phone are hold together using plastic tabs at this point.

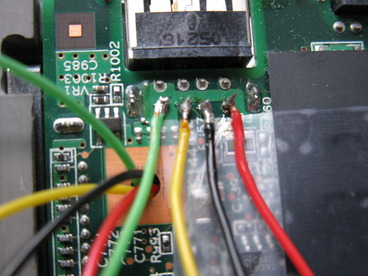

The two connectors from the front and back PCB to the main PCB needs to be detached gently. They will come off without force if you do it right.

Working on the back, you need to detach the PCB where all the buttons are located. Gently use a thin screwdriver for this. You also need to detach the power connector. That is most easily done by putting a screwdriver into the powerconnector, tipping the screwdriver downwards. That will make the connector pop out of its plastic tabs.

Assembling the back is just the reverse process. Keywords are: patience, low force, patience

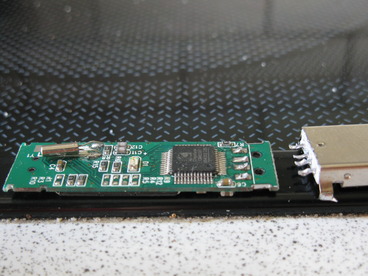

Working on the front part. Unscrew the two screws holding the PCB onto the slider. Do not fall for the urge to do anything about the spring system!! If you do, you will not get a working phone afterwards!

After unscrewing the two screws, you can pull the PCB out of the fascia. I then cleaned the TFT and put the PCB into the new fascia.

Front and back fascia was now done.

Assembly of the parts again. Just reverse the steps you did when taking the phone apart.

And then

And it is still alive, who should have thought that ![]()